安徽美岚矿机的MJ系列颚式破碎机原厂正品配件,能够更有效的保持设备的工作效率和使用周期,使设备拥有较高的使用年限。好的配件,需要经得起砂石的捶打和岁月的磨炼。美岚矿机正品配件,不仅仅是精益求精,更重要的是结实耐用,和设备契合,为客户持久的创造更大价值。

|  |  |

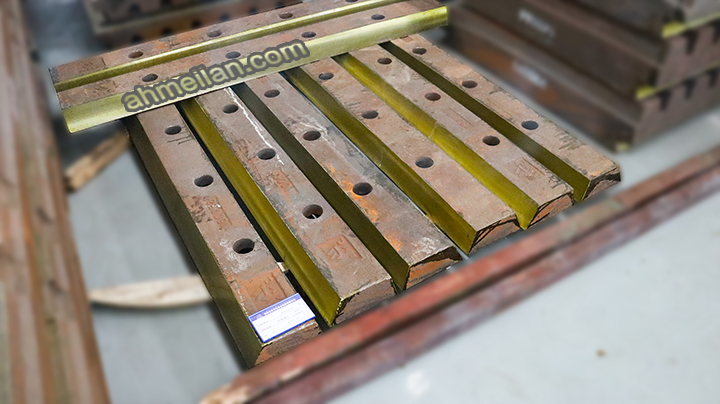

| 颚式破碎机 固定颚板 | 颚式破碎机 动颚护板 | 颚式破碎机 活动颚板 |

|  |  |

| 颚式破碎机 压条 | 颚式破碎机 轴承座 | 颚式破碎机 弹簧 |

|  |  |

| 颚式破碎机 轴承 | 颚式破碎机 边护板 | 颚式破碎机 拉杆 |

联系我们

安徽美岚智能装备制造有限公司热忱欢迎社会各界与我们联系,我们全天恭候您的垂询!

24小时服务热线: +86-0564-3333039 手机:13865711606

总部地址: 中国安徽六安市金安区城北现代产业园