MC系列单缸液压圆锥破碎机,源自欧美破碎技术结合使用经验研发而成,集机械,液压,电器,智能控制等技术为一体的全新一代圆锥破碎机,结合优化的层压式破碎腔型,全智能自动化控制系统,破碎效率高,生产成本低,维修调整方便,广泛地应用于中碎,细碎及超细碎作业当中。

设备实拍--MC800RX单缸液压圆锥破碎机

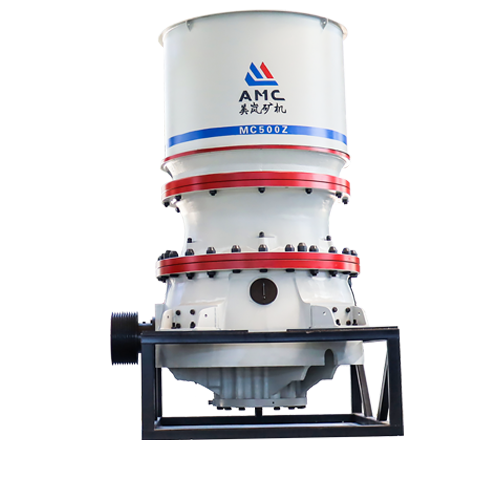

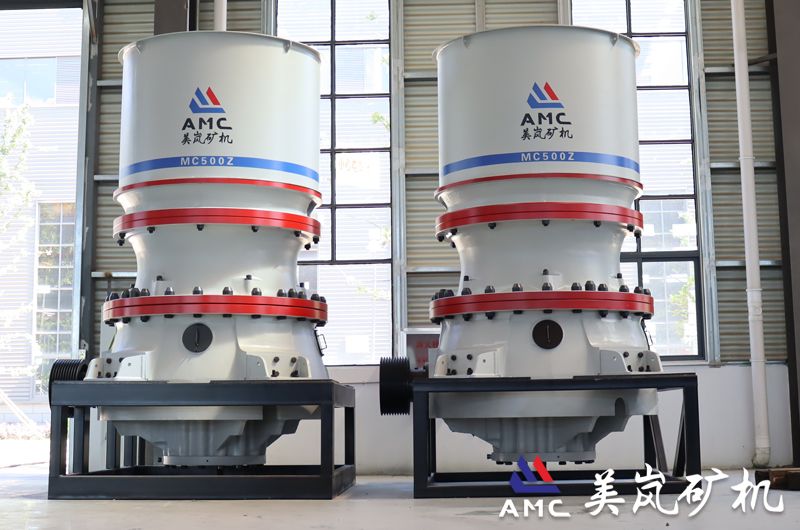

设备实拍--MC500Z单缸液压圆锥破碎机

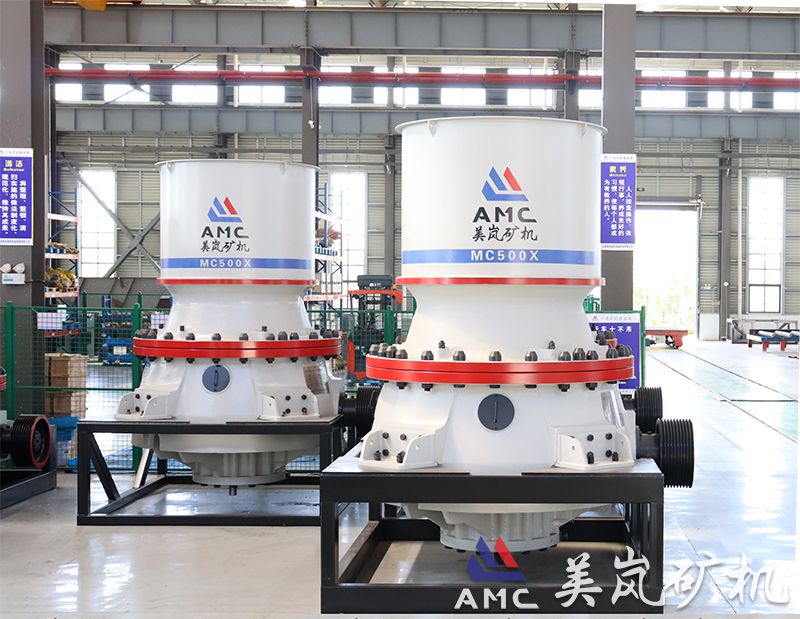

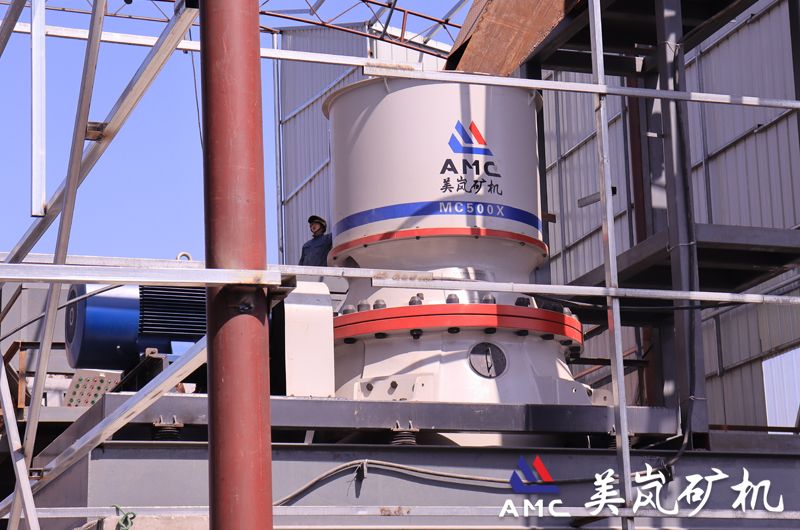

设备实拍--MC500X单缸液压圆锥破碎机

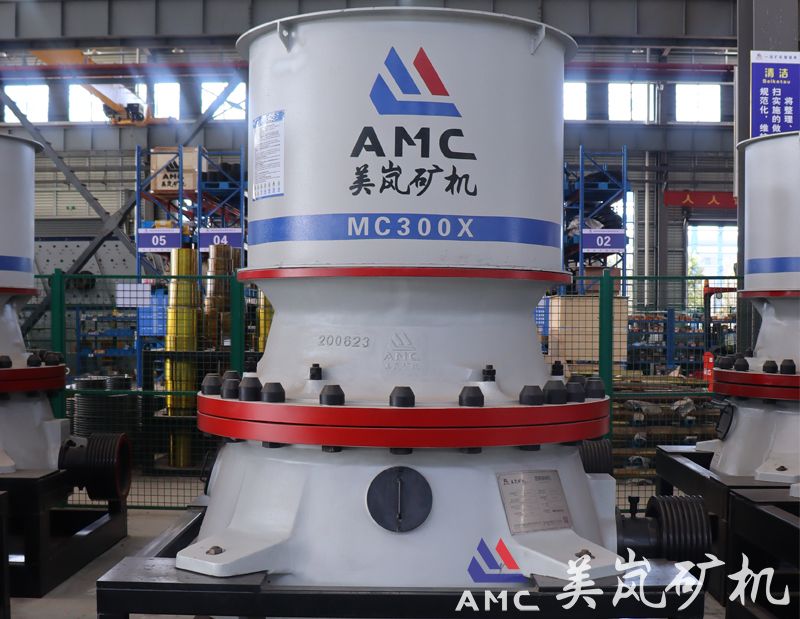

设备实拍--MC300X单缸液压圆锥破碎机

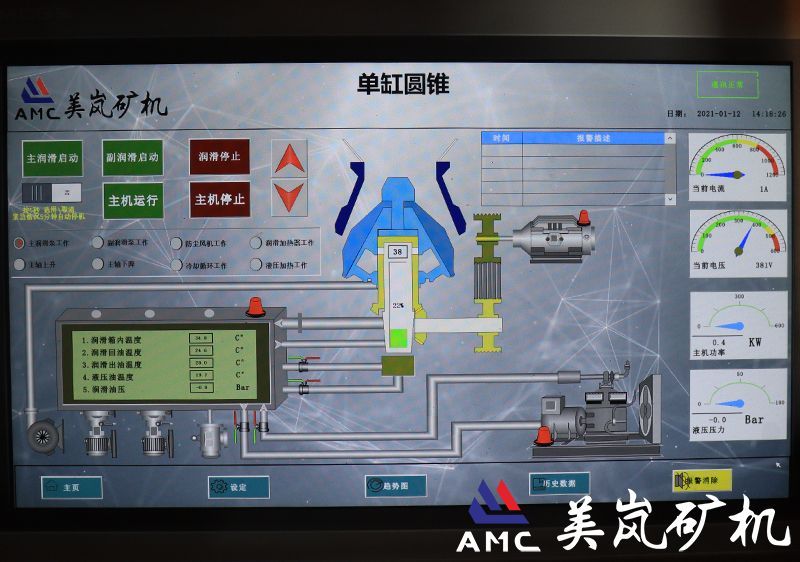

设备实拍--MC系列单缸液压圆锥破碎机PLC

MC系列单缸液压圆锥破碎机工作时:电机带动破碎机的小齿轮,小齿轮带动大齿轮,大齿轮组件(大齿轮、大齿轮架、偏心钢套)带动偏心套组件(偏心缸套、偏心铜套)和主轴组件(主轴、内锥、内锥衬板)以理论垂直线为中心,在铜衬套内公转,主轴组件在偏心铜套内以主轴的中心线可以实现自转。空机运行的时候,偏心套组件“抱着”主轴组件和随大齿轮一同公转,当物料加入到破碎腔后,主轴总成(主轴、内锥)在物料的阻力下在偏心铜套内缓慢的自转。内锥的运行轨迹看起来是在破碎腔内来回摆动,同时缓慢的旋转。物料被摆动的内锥挤压破碎。支撑套与架体连接处靠液压缸压紧,当破碎机内落入金属块等不可破碎物体时,单缸的动锥由底部液压活塞托起,起到排放口调整和过铁保护、反复起落排除堵矿的作用。

客户考察--MC系列单缸液压圆锥破碎机

设备出厂--MC系列单缸液压圆锥破碎机

MC系列单缸液压圆锥破碎机,是由安徽美岚智能装备制造有限公司(AMC)根据CAE及有限元分析,结合实际应用环境,自主研发并生产的新型液压圆锥破碎机,MC系列单缸液压圆锥破碎机,集机械、精密加工、液压、电气、自动化和智能化控制等技术为一体,对关键部件进行了突破性创新设计,使之成为中硬度物料中碎和细碎时的优选设备。美岚矿机通过将破碎腔型、偏心距与运动参数完美配合,实现了更高的生产效率、更优的产品质量;结合优化后的强度设计和高质量的耐磨材料,使设备的承载能力更强、破碎比更大;为了确保设备在破碎时的安全平稳运行,我们采用了大量的自动化设计,如自动化过铁保护,用户无需停机,破碎过程中机器自动调整排料口释放异物;当给料量过大,机器过载时,电机通过热保护自动停机,避免过载损伤机体;自主开发的PLC智能控制系统,可以连续监测并记录破碎机内部实际负荷,从而优化破碎机的利用率,使破碎机在所有时间内都能发挥其优秀性能;正压防尘系统能够保证破碎腔内部压力始终高于外部压力,有效的防止灰尘和其他小颗粒进入润滑系统,避免了对润滑系统污染,从而减少了维护工作量并延长了润滑系统和设备的使用寿命。

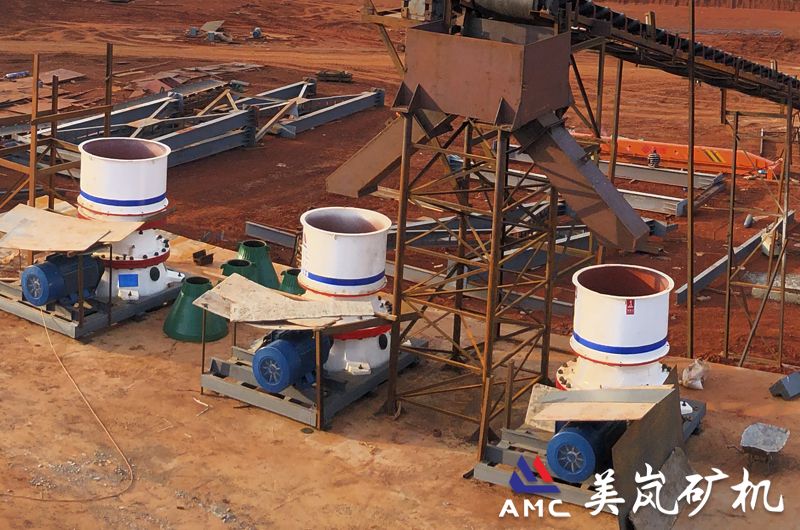

设备安装--MC300Z单缸液压圆锥破碎机

工作现场--MC500X单缸液压圆锥破碎机

工作现场--MC500X单缸液压圆锥破碎机

工作现场--MC300Z单缸液压圆锥破碎机

工作现场--MC系列单缸液压圆锥破碎机

| 型号 | 腔型 |

最大进料尺寸 (mm) |

排料口尺寸 (mm) |

装机功率 (kw) |

处理能力 (t/h) |

偏心距选项 (mm) |

| MC100X | EC(超粗型) | 150 | 13-35 | 90 | 55-180 | 16\20\25 |

| M(中型) | 65 | |||||

| MC200X | EC(超粗型) | 180 | 13-35 | 160 | 110-320 | 18\25\28 |

| M(中型) | 90 | |||||

| MC300X | EC(超粗型) | 260 | 19-40 | 250 | 170-420 | 25\32\40 |

| C(粗型) | 180 | |||||

| M(中型) | 120 | |||||

| MC500X | EC(超粗型) | 280 | 19-40 | 315 | 350-650 | 25\32\40 |

| C(粗型) | 220 | |||||

| MF(中细型) | 125 | |||||

| MC800RX | EC(超粗型) | 320 | 19-40 | 560 | 430-800 | 32\40\54 |

| C(粗型) | 220 | |||||

| M(中型) | 160 |

| 型号 | 腔型 |

最大进料尺寸 (mm) |

排料口尺寸 (mm) |

装机功率 (kw) |

处理能力 (t/h) |

偏心距选项 (mm) |

| MC100Z | EC(超粗型) | 250 | 19-40 | 90 | 85-260 | 16\20\25 |

| M(中型) | 150 | |||||

| MC200Z | EC(超粗型) | 380 | 19-45 | 160 | 135-420 | 18\25\28 |

| C(粗型) | 280 | |||||

| MC300Z | C(粗型) | 380 | 25-50 | 250 | 275-600 | 18\25\32\40 |

| MF(中细型) | 280 | |||||

| MC500Z | C(粗型) | 500 | 45-70 | 315 | 595-1160 | 18\25\32\40 |

| MF(中细型) | 320 | |||||

| MC800RZ | C(粗型) | 550 | 45-75 | 560 | 731-1850 | 32\40\54 |

| MF(中细型) | 320 |

注:上表中给出的破碎机生产能力可作为初步选型参考,表中数据是基于物料松散密度为1600kg/m³所对应的条件是开路破碎,其给料尺寸满足破碎机允许的最大给料粒度,且不含小于破碎机紧边排料口尺寸的物料,比如有预先筛分开路作业条件下的生产能力;在给料中细粒级含量较高,比如闭路作业条件下,生产能力比开路生产能力高15-30%。由于物料类型、给料级配、含水率、安装的衬板类型及其材料种类的不同等,都会影响破碎机的生产能力,实际生产的结果与表中会有差异,为了选择适合您特定条件下使用的破碎机,请向美岚矿机咨询。

年产500万吨花岗岩石子生产线现场(MC系列单缸液压圆锥破碎机)

常见砂石破碎生产线设备配置(颚式破碎机+单缸液压圆锥破碎机)

联系我们

安徽美岚智能装备制造有限公司热忱欢迎社会各界与我们联系,我们全天恭候您的垂询!

24小时服务热线: +86-0564-3333039 手机:13865711606

总部地址: 中国安徽六安市金安区城北现代产业园